Specification

|

ITEM

|

VALUE

|

|

Place of Origin

|

China

|

|

Zhejiang

|

|

|

Brand Name

|

SANYUE

|

|

Model Number

|

YSQ3R-100/3P

|

|

Frame current

|

100

|

|

Product name

|

Automatic Transfer Switch

|

|

Type

|

PC Level

|

|

Pole

|

3P

|

|

Rated Current

|

100A

|

|

Rated Voltage

|

230V

|

|

Insullation voltage

|

690V

|

|

Control voltage

|

220V

|

|

Impact resistant voltage

|

8KV

|

|

Rated froquency

|

50/60Hz

|

|

Standard

|

IEC60947-11

|

|

Customized support

|

OEM/ODM

|

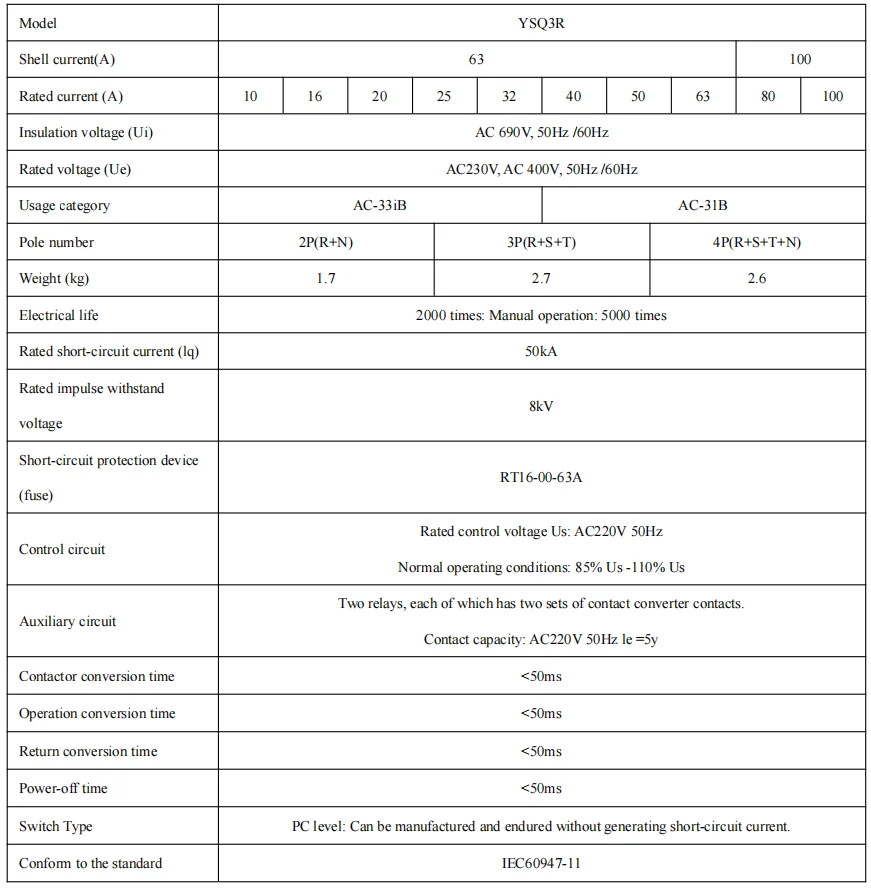

1. Conform to the standard: GB/T14048.11 / IEC60947-11

2. Product features: No power outage, fast switching speed

3. Conversion mode: Municipal electricity and power generation, municipal electricity and photovoltaic

4. Product structure: Two-stage, rail-mounted type, low failure rate, convenient for maintenance, reliable performance

|

Enterprise

Code

|

Product

Code

|

Rail

Mounted

|

Shell

Current

|

Pole

Number

|

Rated operating voltage

|

Rated operating current

|

|

YS

|

Q3

|

R

|

63

100

|

2P

3P

4P

|

AC110V

AC220V

AC380V

|

10A 16A 20A 25A

32A 40A 50A 63A

80A 100A

|

1) Ambient air temperature: The maximum temperature shall not exceed 40℃, the minimum temperature shall not be lower than -5℃, and the average temperature within 24 hours shall not exceed 35℃.

2) Altitude: The altitude of the installation site should not exceed 2000 meters.

3) Atmospheric conditions: When the maximum temperature reaches 40℃, the relative humidity of the installation site should not exceed 50%. When the temperature is the minimum temperature -5℃ and the relative humidity is high, for example: when the temperature is 25℃,the relative humidity is 90%. Due to temperature changes, special protective measures should be taken to deal with the occasional condensation phenomenon on the product surface.

4) Pollution level: The pollution level of TSE complies with the designated level 3 of GB/T 14048.11.

5) Installation category: The installation type of TSE is in line with the specified category in GB/t14048.11

6) Installation conditions: The TSE can be vertically installed in the control cabinet or distribution cabinet. Ensure that the installation distance complies with the requirements please.

Important Notes

Manual / Automatic operation

SE can guarantee the performance of power generation and power-off during circuit operation. However, for manual operation, due to the differences in power generation and power-off speed or the operator, SE cannot guarantee the above performance. During the manual power generation and power-off process, excessive silver alloy loss may occur. Therefore, when all power cut checks and maintenance operations are carried out, simply pull the selector switch to the manual position. Generally, please pull the selector switch to the automatic position. When operating manually, pull the selector switch to the manual position. After the manual operation is completed, pull the selector switch from the manual position to the automatic position.

SE will become active instantly. After the conversion is completed, the coil in the control circuit will be disconnected by the internal converter. At the rated voltage of 80% to 110%, the coil can operate normally. A too low voltage will cause the coil to heat up or even catch fire.

Installation and Wiring

1) Before installation, please check the integrity of the TSE. Then use the operating handle to open and close the TSE, check the flexibility of the transmission device, and detect the generation and disconnection conditions of the load at each stage of the normal and backup power supply.

2) Detection control voltage: AC50Hz AC220V. The coil in the control circuit should not be too long. The cross-sectional area of the copper wire should not be greater than 2.0mm².

3) According to the requirements of the distribution system installation, please equip the appropriate circuit breakers to ensure the safety of the staff and equipment.

Maintenance, inspection and storage

Repair and inspection should be operated by professionals. All power supplies should be cut off in advance.

To ensure the good performance of the TSE, the first maintenance and inspection should be carried out within 6 months after use, and at least once a year for maintenance and inspection. In harsh installation conditions, the frequency of maintenance and inspection should be increased.

The TSE should be stored in an environment comparable to the normal working environment, with measures to prevent dust, moisture and bumping.

Maintenance and inspection items

a. Please remove dust and dirt when there is a malfunction.

b. Please check whether the contact components of the electrical contacts are deformed or damaged, and remove the coked metal particles attached to the surface and around.

c. Rust, acidification and dust on the contact surface may cause poor contact. Please operate manually several times and measure the contact resistance if necessary.

d. Due to long-term dampness and being in a suspended state, please dry the TSE before use. After removing dust and dirt, use a 500V megohmmeter to measure the insulation resistance for normal supply, alternate supply, and the load side rods, including the insulation resistance between the live components and the metal plate. Moreover, the insulation resistance should not be less than 10MΩ.